Demonstrate the strength! LONGi Magnetic Flotation Separator Helps Green innovation of Copper Tailings Resource Utilization Process in South America!

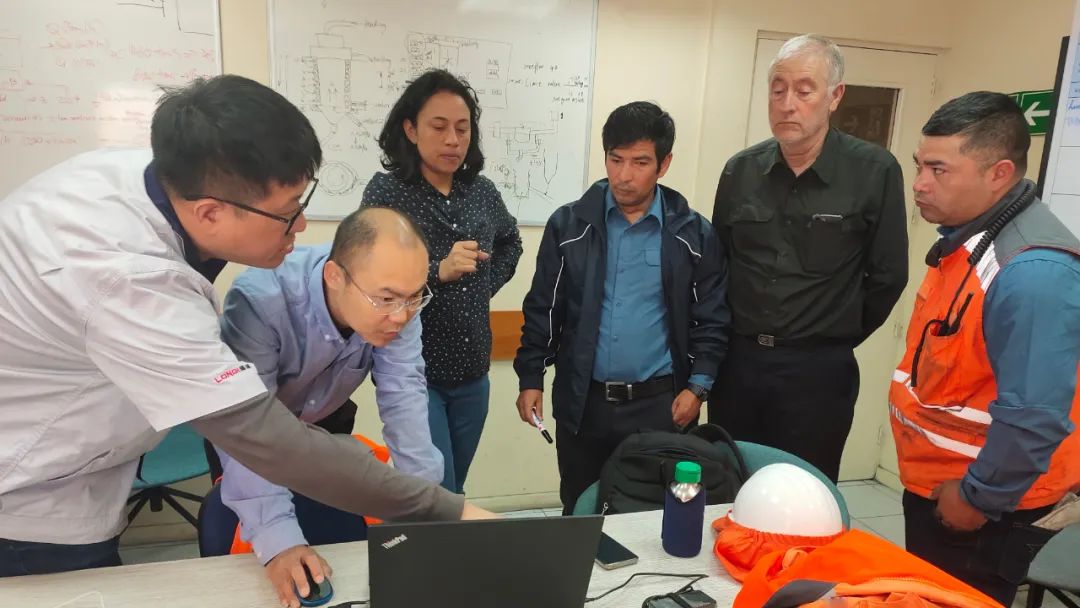

Recently, LONGi Magnetic Flotation Separator has successfully completed commissioning in a well-known copper mine in South America. This is the first application of Chinese Magnetic Flotation Separator in the magnetic separation process of copper tailings in South America, which is a milestone in the green innovation of the local copper tailings resource utilization process.

South America, this fiery continent, has the world's largest copper resources. It is like a vigorous beating heart, constantly delivering precious "metal blood" to the world.

However, the mining and smelting of copper ore will discharge a large amount of copper tailings. The flotation process is generally used in the recovery of iron concentrate from copper tailings. Since the flotation method requires a large amount of flotation agents, enterprises are faced with high water consumption, high agent costs, high operating costs and other problems, which also have a great impact on the local environment.

LONGi Magnetic Flotation adopts physical separation, which has the features of low power consumption, no need to add flotation agents and low operating cost, and is the best alternative to the traditional flotation process. The automation degree of the equipment is much higher than that of traditional flotation equipment, which fully meets the needs of automated and intelligent mine construction, and is very suitable for enterprises that need to reduce human participation.

Adhering to the internationalization strategy unswervingly, more and more "LONGi figures" appear in the mine construction sites around the world. LONGi continues to focus on the efficient utilization of resources, promotes the green and intelligent development of equipment and solutions, and contributes more LONGi power to global mine construction.