The WTM Intelligent Vertical Stirring Mill (Tower Mill)

- LONGi

- Liao Ning

- 90 dahs

- 100 sets

WTM intelligent vertical mill is dedicated to the high-efficiency dissociation of minerals, providing users with energy-saving, consumption-reducing, quality-enhancing and efficiency-enhancing solutions, realizing maximum monomer dissociation of minerals, and laying a solid foundation for quality improvement and efficiency enhancement,

In recent years, with the continuous consumption of high-grade ores, the characteristics of poor, fine and miscellaneous minerals have become prominent, and the sorting and processing of low-grade and refractory ores has become the main direction of research and development in the mining industry. WTM intelligent vertical mill is dedicated to the high-efficiency dissociation of minerals, providing users with energy-saving, consumption-reducing, quality-enhancing and efficiency-enhancing solutions, realizing maximum monomer dissociation of minerals, and laying a solid foundation for quality improvement and efficiency enhancement.

Product Specification and Performance Parameters

Model | Power(kw) | Processing Capacity(t/h) | Dimensions(length*width*height)mm |

WTM-075 | 75 | 6-8 | 2400*2400*7500 |

WTM-112 | 112 | 10-12 | 2400*2400*7800 |

WTM-220 | 220 | 22-25 | 2800*2800*9350 |

WTM-280 | 280 | 30-35 | 3000*3000*9750 |

WTM-355 | 355 | 35-40 | 3300*3300*11500 |

WTM-560 | 560 | 55-60 | 3800*3800*12400 |

WTM-710 | 710 | 70-75 | 4300*4300*13200 |

WTM-850 | 850 | 85-90 | 4300*4300*13700 |

WTM-1000 | 1000 | 100-105 | 4300*4300*14100 |

WTM-1120 | 1120 | 110-120 | 4650*4650*14100 |

WTM-1300 | 1300 | 135-140 | 4650*4650*14300 |

WTM-1500 | 1500 | 150-160 | 4950*4950*14900 |

WTM-1850 | 1850 | 185-200 | 4950*4950*15500 |

WTM-2250 | 2250 | 225-250 | 6000*6000*17200 |

WTM-3300 | 3300 | 330-350 | 7200*7200*18900 |

Note: The processing capacity is calculated as 60%~70% of the feed particle size -200 mesh, and 85%~95% of the product particle size -400 mesh.

Product Properties Advantages

* Remote intelligent control system, 24-hour maintenance service guarantee

* Nano-composite spiral liner with stronger wear resistance

* Optimized spiral design with high efficiency

* World-class drive system configuration with stronger reliability

* High efficient and professional expert service team to provide system solution

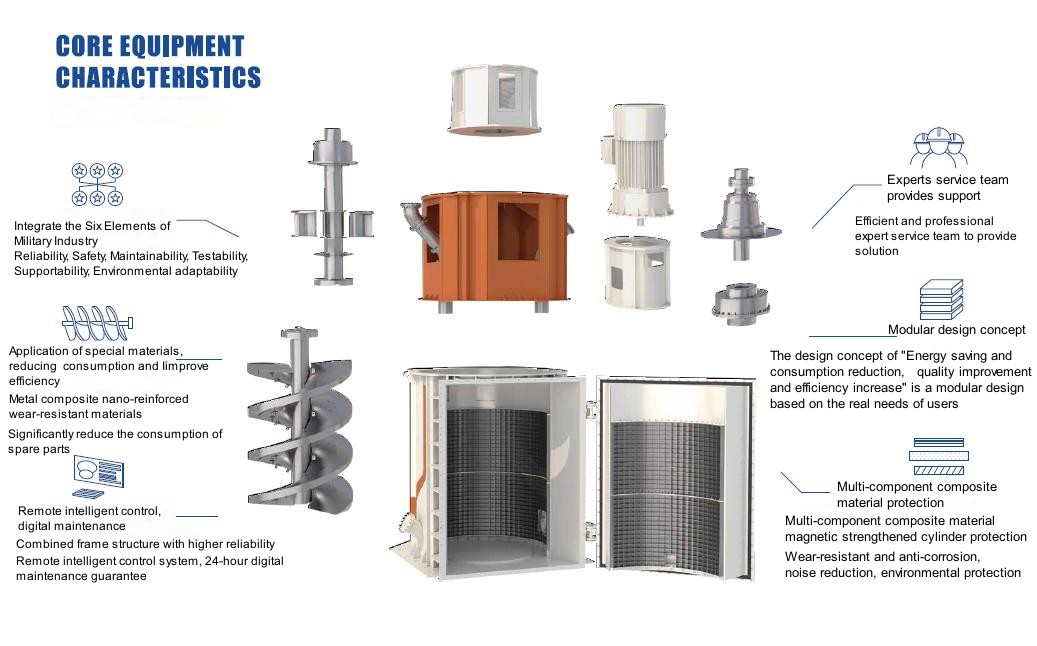

Product Core Characteristics

1. Integrate the Six Elements of Military Industry

* Reliability, Safety, Maintainability, Testability, Supportability, Environmental adaptability

2. Application of special materials, reducing consumption and improve efficiency

* Metal composite nano-reinforced wear-resistant materials

* Significantly reduce the consumption of spare parts

* Improve the economic efficiency of production and operation

3. Remote intelligent control, digital maintenance

* Combined frame structure with higher reliability

* Remote intelligent control system, 24-hour digital maintenance guarantee

4. Experts service team provides support

* Efficient and professional expert service team to provide solutions

5. Modular design concept

* The design concept of "Energy saving and consumption reduction, quality improvement and efficiency increase” is a modular design based on the real on the real needs of users.

6. Multi-component composite material protection technology

* Multi-component composite material protection magnetic strengthened cylinder protection technology, wear-resistant and anti-corrosion, noise reduction, environmental protection

Application Scope

WTM Intelligent Vertical Grinding Mill is mainly used for grinding fine-grained material, the output particle size is 20~00 μm, which is mainly used for the second stage grinding and the third stage grinding in the grinding process.

It is used in the fine crushing of iron ore, lead-zinc ore, copper ore, vanadium-titanium magnetite, gold ore, titanium dioxide, graphite ore, quartz placer and other fields.