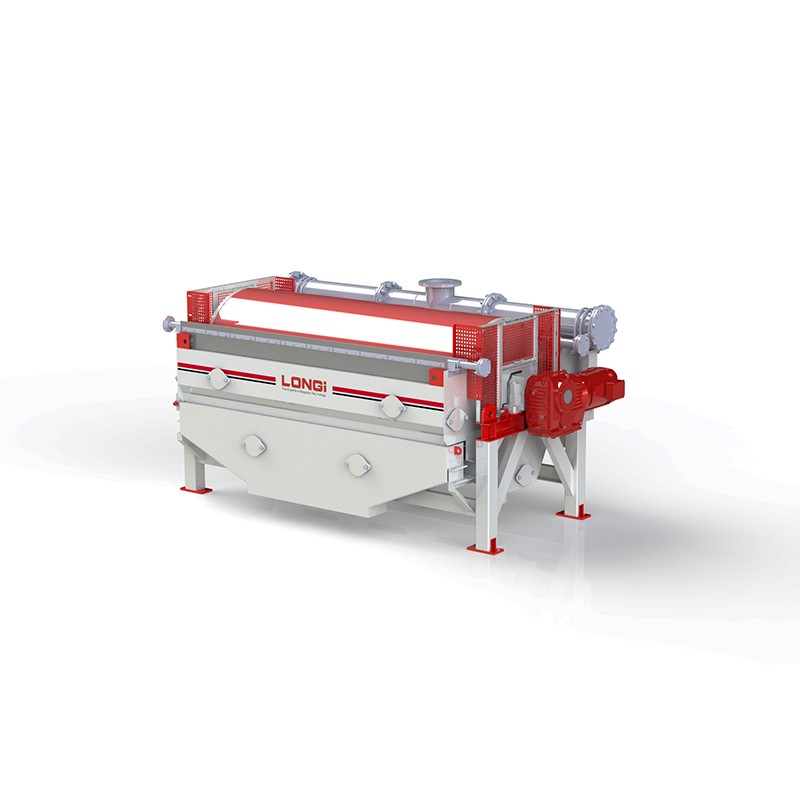

Automatic Flotation Magnetic Separator

- LONGi

- China

- 40days

- 200sets

The development of the automatic magnetic separator was caused by a breakthrough based on research of dewatering tanks, magnetic flocculations, magnetic columns, wash mills and the like. This innovation allows for a large capacity unit capable of greatly increasing the concentrate grade automatically in a reliable environment while also saving on water and power.

Automatic Flotation Magnetic Separator Description

The development of the automatic magnetic separator was caused by a breakthrough based on research of dewatering tanks, magnetic flocculations, magnetic columns, wash mills and the like. This innovation allows for a large capacity unit capable of greatly increasing the concentrate grade automatically in a reliable environment while also saving on water and power.

Automatic Flotation Magnetic Separator Features:

1) A large Increase in The Concentrate Grade

A positive and neAutomatic Flotation Magnetic Separatorgative pulsation of the magnetic field allows for the particle to be loosely suspended in a slurry for a thorough discharge of the gangue and intergrowth. This enables the separator to both effectively improve the grade of the magnetic concentrate and control the magnetic material from draining into the tailings.

2) High Degree of Automation

The water and slurry volume, overflow density, discharge density and magnetic intensity is all automatically adjusted based on the specific properties of the minerals. This virtually guarantees the best separation possible throughout the process, even when the material's properties change through normal fluctuations of ore grade.

3) Simplify Process Flow

The magnetic flotation separator can replace the traditional finisher magnetic separator. By doing so it not only less the amount of equipment needed to complete the process, but, also reduces both water and power consumption.

4) Stable Separation

By means of having a larger separation area the amount of fluctuations in the end product that caused by the unstable feed rate are greatly reduced. When the change of material is within 60% of the normal feed, the end user can expect a stable and consistent product.

5) Power & Water-Saving

Positive and negative pulsations of the magnetic field, automatic feed control over the water and slurry levels as well as the magnetic intensity all allow for the maximization of resource use.

6) Remotely Control

Using a PLC module the unit can easily be monitored and adjusted, if ever desired, from the end user computer system in the central control room.

7) Adaptable Capacity

Based on the customer's needs, there are models ranging from the LJC-2000 to LJC-10000. This allows the end user to select a device capacity of processing for their needs, up to 80 tons per hour per unit.

The magnetic flotation separator is generally utilized in the finishing separation stage. It was designed for use ferromagnetic minerals with a susceptibility higher than 3000x 10-6 cm/g and has been found to normally increase the concentrate grade by 2-9% which can greatly increase the systems overall efficiency.

LONGi’s Service Guarantee

One on One Service

LONGi’s in house laboratory is well known for providing professional and accurate sample testing for a wide variety of clients in both the mineral and recycling industries. Based on the lab test results and often a necessary site survey our experienced engineers are proud to be able to offer the best solution available every time we can. Not only do we look for the solution to best process the end users material, but, we are mindful to provide the best value and performance in the most economical way.

Valuable Site Service

LONGi is proud to be able to provide experienced mechanical, electrical and magnetic engineers able to assist with most any installation, commissioning or training issues that may arise. Our main goal is to eliminate any situations before they arise at the work site both before and after the project. LONGi also has strategically located offices within easy access to current and future operating sites to provide spare parts and service and allow for minimal down time.

Ongoing Feedback Service

LONGi is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude LONGi makes it a point that past sales are just as important as the future. Because of this LONGi will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.