Magnetic Separator

-

Electromagnetic separator

1、Electromagnetic Separator have better insulation performance, low temperature rise, light weight, good durability, rapid heat releasing, strong magnetic force, strong catching ability, high separating rate etc.

Email Details

2、Electromagnetic Separator are widely used for removing ferrous materials in some fields using coal as fuel, such as thermal power station, coal plant, metallurgy, cement plant, glass plant, foodstuff, port, etc. It can purify the materials and improve the quality of material to protect the equipment downstream. -

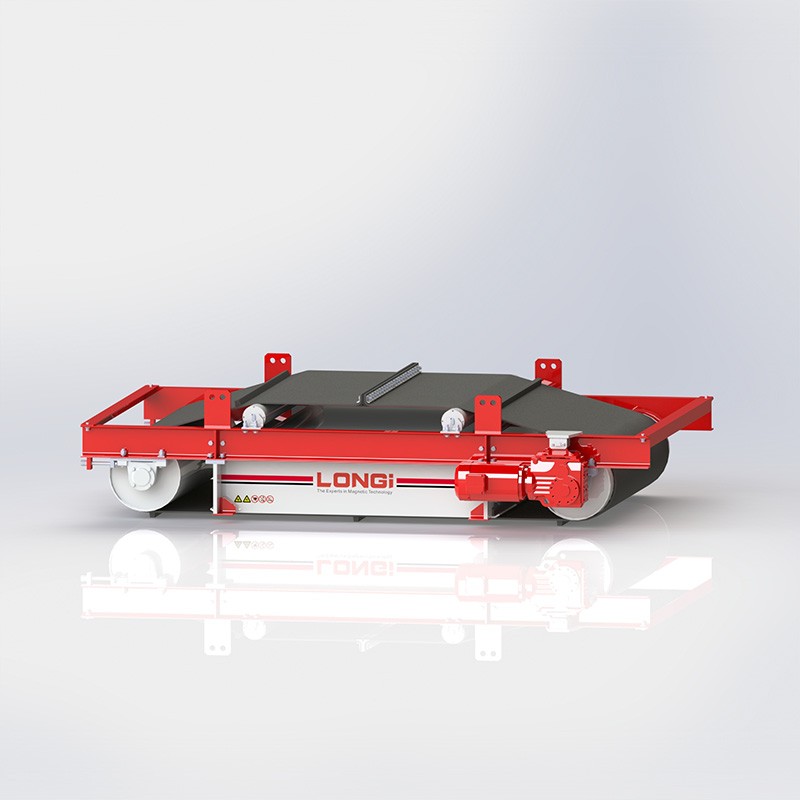

Magnetic Separator

The series magnetic separator separates magnetic material and tramp iron by using a unipue arrangement of magnetic fields with little or no magnetic ore being removed to protect downstream crushing equipment.

Email Details -

Permanent magnetic separator

1、Permanent Magnetic Separator is design with the principle that magnetic iron contamination can be attracted by permanent magnet. A strong magnetic field is formed below magnetic separator. When materials run below separator, iron contamination hidden in material will be attracted on the working surface of separator.

Email Details

2、Move the Permanent Magnetic Separator away from belt conveyor when separator has attracted a certain amount of iron, and remove iron on separator with non-magnetic tools. Separator can continue to work after cleaning.