Wet High Intensity Magnetic Separator

-

Hot

Wet high intensity magnetic separator for metal material

1、Wet high intensity magnetic separator Utilizes a vertical ring configuration for smooth operation and prevention of jams.

2、Wet high intensity magnetic separator Enhances concentrate grades and recovery for optimal metal separation.

3、Wet high intensity magnetic separator Adjustable magnetic intensity for diverse applications, suitable for various ferrous and non-ferrous materials.Wet high intensity magnetic separator for ferrious material Wet high intensity magnetic separator WHIMSEmail Details -

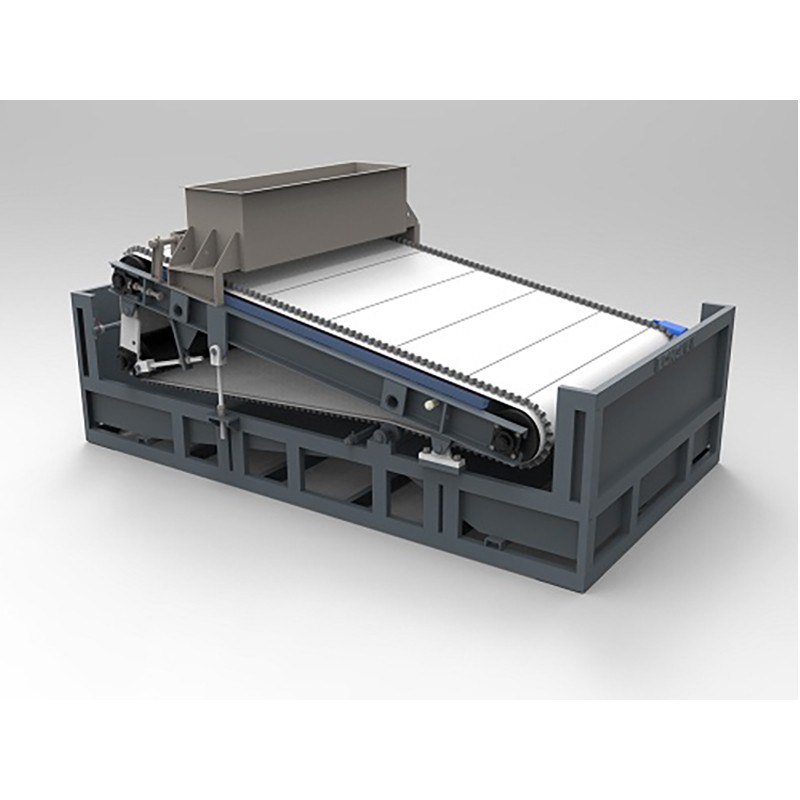

Wet Belt Magnetic Separator

1、The wet belt magnetic separator is a permanent separator made by using high quality NdFeB magnetic elements.

Email Details

2、The wet belt magnetic separator surface intensity can reach up to 1.3T, this removes the ferrous minerals comingled with non-ferrous minerals efficientively.

3、The wet belt magnetic separator is made as a belt structure, the minerals are agitated and separated multuiple times at the separation area from the input point to the output point, in order to remove the ferrous minerals and achieve a purified mineral.

4、The wet belt magnetic separator is developed by integrated hydraulics, magnetics and mechanics, which produce a super magnetic intensity and strong gradient processing area. the wet belt magnetic separator can be used widely in different kinds of non-ferrous mineral industries. -

High Gradient Magnetic Filter

High gradient magnetic filter is a newly developed product by LONGi Magnet based on years of research and absorbing advantages of similar products. It can help abide burst accident according to increase the corrosion resistance of pipe, promote the recovery of condensation water, and decrease thickness of iron oxide scale.

Email Details -

Wet high intensity magnetic separator for non-metal material

1、Achieve a stronger magnetic strength with a background intensity of 1.3T, allowing the inducted magnetic intensity to reach up to 2.6T for efficient mineral separation.

2、The coil of this magnetic separator requires no regular cleaning, and it utilizes H class insulation for long-lasting performance.

3、Operate the equipment safely with a safety transformer that eliminates the occurrence of ground circles on the excitation coil.Wet high intensity magnetic separator for non-ferrous material non-ferrous material magnetic separator high intensity magnetic separatorEmail Details