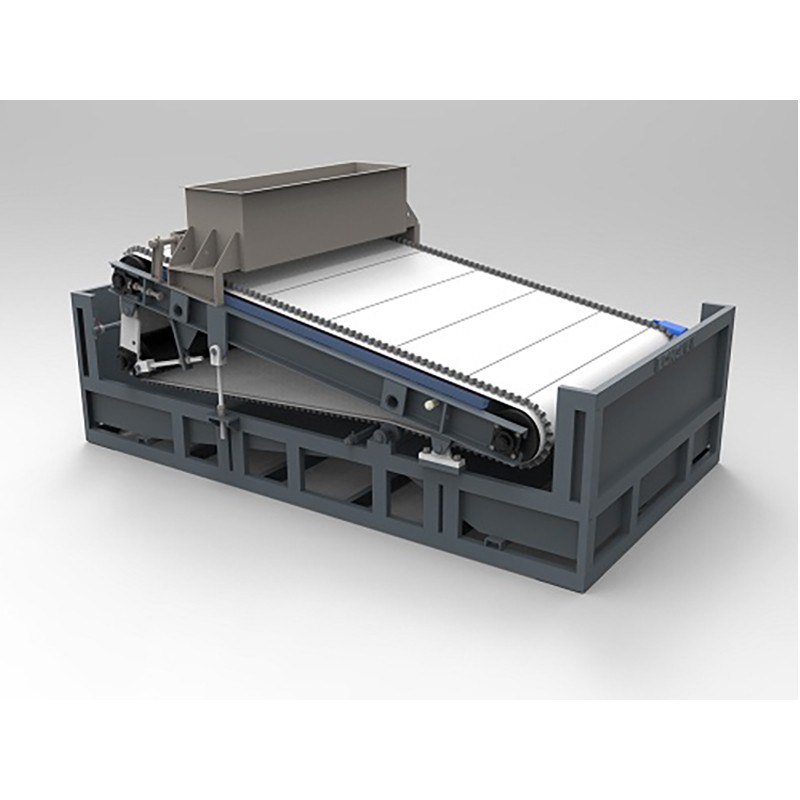

High Gradient Magnetic Filter

- LONGi

- China

- 30days

- 200sets

High gradient magnetic filter is a newly developed product by LONGi Magnet based on years of research and absorbing advantages of similar products. It can help abide burst accident according to increase the corrosion resistance of pipe, promote the recovery of condensation water, and decrease thickness of iron oxide scale.

High Gradient Magnetic Filter Description

High gradient magnetic filter is a newly developed product by LONGi Magnet based on years of research and absorbing advantages of similar products. It can help abide burst accident according to increase the corrosion resistance of pipe, promote the recovery of condensation water, and decrease thickness of iron oxide scale.

High Gradient Magnetic Filter Features:

Maintenance Free——no need to change filters

1、The core of The High Gradient Magnetic Filter is made by special stainless steel. It is corrosion resistant and wear-resistant. The High Gradient Magnetic Filter employs impulsing steam-water with combination back flushing. The configuration of the filter cores are from sparse to dense making it well suited for back flushing. The life time of the filter core can be more than 10 years.

2、High efficiency——apply to high-temperature 180℃;available to remove 0.03μm~150 μm iron oxide.

The Filter core is made of a highly magnetic gathering soft magnetic steel, suitable for 180℃ condensation water. The external magnetic field and the wall of container are equipped with thermal-protective coating, which isolate the internal heat conduction well.

The cooling system is a combination of forced oil cooling and water cooling.

The filter core is made of high magnetic gathering stainless steel, 20000Gs magnetic intensity and 1000Gs/μm. The magnetic gradient is generated under the external magnetic field. The configuration of the filter cores are from sparse to dense, in order to absorb all of the 150 μm ~0.03μm magnetic suspended solid and colloid while water flows through the filter. Removal rate of magnetic objects in the water is above 99.5%, and iron content in outlet water is lower than 5mg/L.

3、Energy conservation——low operation cost

The only operation cost of high gradient magnetic filter is the power consumption. Decreasing the excitation while higher water quality is available can help to decrease the power cost.

4、Low investment——Less pumps invested

The operation pressure difference is only 0.02Mpa~0.03Mpa so there is no need to add any pumps for existing projects.

5、Convenient operation——With a touch screen control panel and a computer interaction link control is available both on site and remotely.

It is widely applied in electric power industry and nuclear power industry. The high gradient magnetic filter can control magnetic impurity content in the condensation water as the pre-cleaning magnetic filter.

High gradient magnetic filter can protect high speed mixed bed and powdex filter from other impurities. It can help to extend service life for one more time of the furnace pickling, regeneration period of high-speed mixed bed regenerating, and powdex filter wearing layer.

It is specially difficult to recover thermal net condensation water in the power plant that changing power supply in old plant, super-critical co-generation units in new plant. The high gradient magnetic filter is widely applied for iron content below 1000μg/l,and 180℃ to cut down start time. there is no other maintenance cost expect power.

LONGi’s Service Guarantee

One on One Service

LONGi’s in house laboratory is well known for providing professional and accurate sample testing for a wide variety of clients in both the mineral and recycling industries. Based on the lab test results and often a necessary site survey our experienced engineers are proud to be able to offer the best solution available every time we can. Not only do we look for the solution to best process the end users material, but, we are mindful to provide the best value and performance in the most economical way.

Valuable Site Service

LONGi is proud to be able to provide experienced mechanical, electrical and magnetic engineers able to assist with most any installation, commissioning or training issues that may arise. Our main goal is to eliminate any situations before they arise at the work site both before and after the project. LONGi also has strategically located offices within easy access to current and future operating sites to provide spare parts and service and allow for minimal down time.

Ongoing Feedback Service

LONGi is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude LONGi makes it a point that past sales are just as important as the future. Because of this LONGi will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.