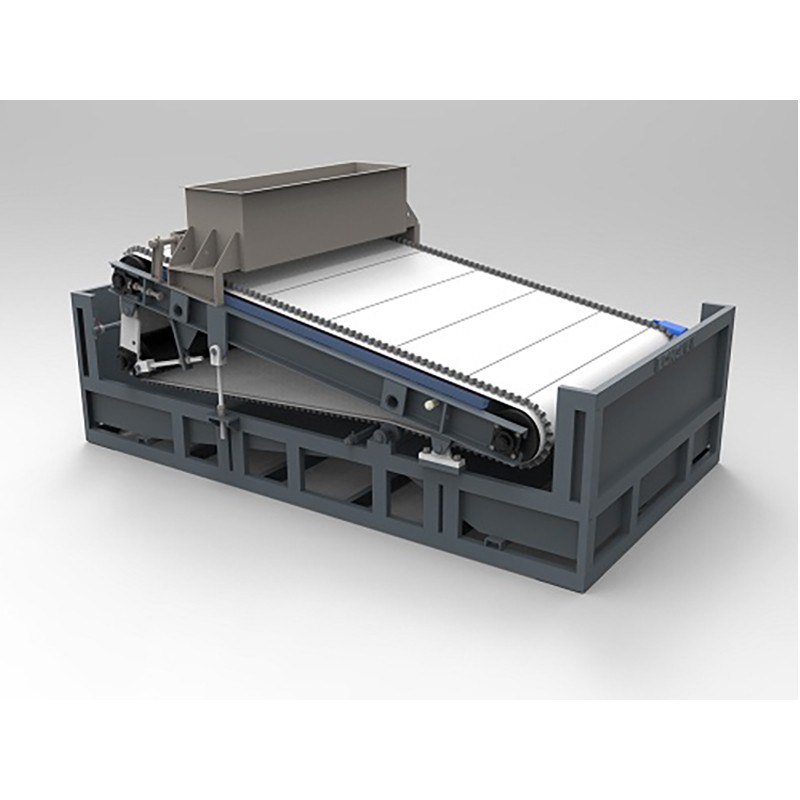

Wet high intensity magnetic separator for non-metal material

- LONGi

- China

- 40days

- 200sets

1、Achieve a stronger magnetic strength with a background intensity of 1.3T, allowing the inducted magnetic intensity to reach up to 2.6T for efficient mineral separation.

2、The coil of this magnetic separator requires no regular cleaning, and it utilizes H class insulation for long-lasting performance.

3、Operate the equipment safely with a safety transformer that eliminates the occurrence of ground circles on the excitation coil.

Wet high intensity magnetic separator for non-metal material Application

The LGS series WHIMS is widely used to purify quartz, feldspar, kaolin, spodumene, zirconite, nepheline, fluorite, sillimanite and many other non-ferrous minerals while wet and can be used with the weakly ferrous minerals such as hematite, martite, limonite, vanadium-titanium magnetite, manganese, wolframite, tantalum-niobium ores and others.

Wet high intensity magnetic separator for non-metal material Features

1、The wet high intensity magnetic separator is designed with advanced FEA technology to ensure optimal magnetic field simulation and improve process results.

2、Achieve a stronger magnetic strength with a background intensity of 1.3T, allowing the inducted magnetic intensity to reach up to 2.6T for efficient mineral separation.

3、The coil of this magnetic separator requires no regular cleaning, and it utilizes H class insulation for long-lasting performance.

4、Operate the equipment safely with a safety transformer that eliminates the occurrence of ground circles on the excitation coil.

5、Low current controls minimize the risk of accidents and ensure safe operation.

6、Customize the running speed of the ring and pulsating frequency to achieve accurate adjustments and improved separation results.

LONGi prioritizes the use of internationally recognized electrical and mechanical components, ensuring top-quality parts for the machine.

Customers can rely on locally available spare parts, making it convenient to bring the machine back to factory specifications quickly and easily.

LONGi’s Service Guarantee

One on One Service

LONGi’s in house laboratory is well known for providing professional and accurate sample testing for a wide variety of clients in both the mineral and recycling industries. Based on the lab test results and often a necessary site survey our experienced engineers are proud to be able to offer the best solution available every time we can. Not only do we look for the solution to best process the end users material, but, we are mindful to provide the best value and performance in the most economical way.

Valuable Site Service

LONGi is proud to be able to provide experienced mechanical, electrical and magnetic engineers able to assist with most any installation, commissioning or training issues that may arise. Our main goal is to eliminate any situations before they arise at the work site both before and after the project. LONGi also has strategically located offices within easy access to current and future operating sites to provide spare parts and service and allow for minimal down time.

Ongoing Feedback Service

LONGi is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude LONGi makes it a point that past sales are just as important as the future. Because of this LONGi will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.