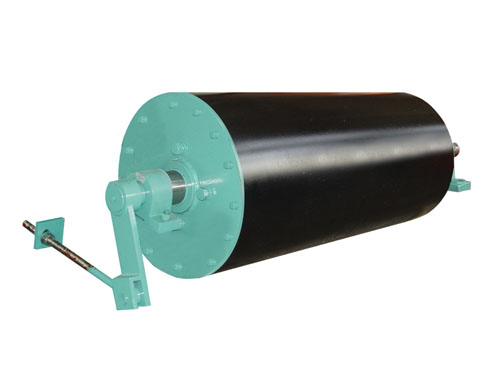

China Brands Wholesale OEM Magnetic Drum Manufacture Factory Quotes

Wet Drum Permanent Magnetic Separator for Iron Ore Mining Processing for Sale: In order to make the coolant purification system of the grinding machine reach a relatively advanced level, a detailed investigation has been carried out on the roll grinding machine of the relevant domestic manufacturers. Its advantage is able to put in a cooling fluid solid iron filings, low investment, deficiency in coolant is another solid phase at the end of the grinding wheel is still not fully separated.

High Efficient Magnetic Separator For Slurry Wet Drum Separation

1, roll grinder original cooling liquid purification system for the backward precipitation type, the cooling fluid through sedimentation tank, make some iron filings and at the end of the grinding wheel into sedimentation tank bottom, continue to recycle after precipitation of coolant, the coolant purification system are the main disadvantages of coolant purification is not completely, there are a lot of scrap iron and at the end of the grinding wheel remaining in the cooling fluid, in this way, will bring a series of problems of roll grinding.

Permanent Fine Ore Drum Magnetic Separator for Mining

2, reduces the level of roll surface roughness, affect the roll surface accuracy because of poor cooling fluid purification, shorten the service life of the cooling fluid, often not only need to change the cooling fluid, but also frequently out at the end of the sedimentation tank at the bottom of the grinding wheel and the iron filings, both to increase the consumption of the cooling fluid, and enhance the labor intensity of workers, and reduce the efficiency of grinding machine.

3. Due to a large amount of grinding wheel dust and iron chips remaining in the coolant, the entire coolant pipeline is often blocked, which affects the use effect of the coolant and causes unnecessary trouble to the maintenance work. Thus it can be seen that the cooling and purifying liquid system of grinding machine must be completely reformed.

The second solution is to use a solid liquid solid three phase separation system, its main principle is the cooling fluid first by magnetic separation system partition, iron filings, was isolated by tape filtration area, isolate another solid phase at the end of the grinding wheel, isolate all slag flow in the same bucket. In this way, the coolant can be completely and thoroughly purified.

Wet Drum Permanent Magnetic Separator for Iron Ore Mining Processing for Sale,Brands,Buy,Cheap,China,Custom,Discount,Factory,Manufacturers,OEM,Price,Promotions,Purchase,Quality,Quotes,Sales,Supply,Wholesale,Produce.