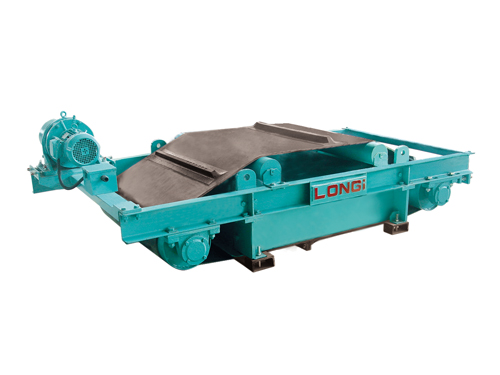

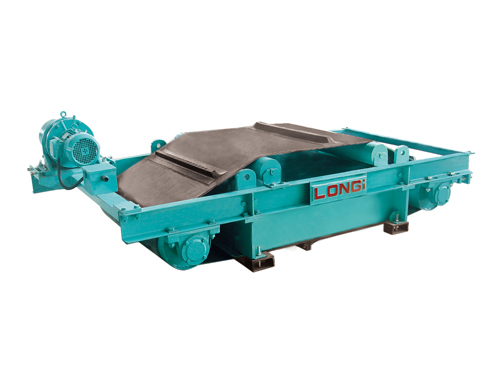

China Brands Wholesale OEM Permanent Magnetic Separator Manufacture Factory Quotes

Buy Auto Cleaning Iron Removing Permanent Magnetic Separator for Conveyor Belt: This equipment has the advanced level, compared with the import similar product is not inferior, moreover its structure is simple, is easy to maintain, the filtration ability is strong, is suitable for the production request. It does not affect the relocation and overhaul of grinding machine, and can be put into production on time.

chrome tantalite wet dry drum permanent magnetic separator for iron ore

According to the appearance size of the three-phase separation device, the magnetic separator designed and drew the construction drawing of the coolant pit, so as to complete the pit construction task as soon as possible during the relocation construction and make preparations for the installation of the separation device. The work was completed before the end of the grinding machine overhaul.

China Plate Type High Gradient Permanent Magnetic Separator

Original coolant circulation system without flushing pipeline facilities, so that a large number of grinding debris deposition in the workpiece, bed and slide bed between the water structure, each shift need manual cleaning, not only increased the labor intensity of workers, and cleaning not clean. In order to improve the working environment of the grinding machine and reduce the labor intensity of the workers, washing pipe facilities are added in this transformation, which can clean the abrasive debris deposited in the water structure and facilitate the maintenance of the grinding machine.

Original grinder to grind and coolant cooled directly into the workpiece between lathe bed and sliding frame bed ditch, effect of corrosion on the lathe bed is, we in this project, with thick aluminum plate compressed into a shape consistent with gully cross-section lining board, laying on the surface ditch and fixed, which can effectively prevent the corrosion of cooling fluid on the lathe bed. Through the above series of transformation work, not only the cooling liquid purification system of the grinding machine has been thoroughly transformed, making it reach the advanced level, but also add flushing pipeline facilities and ditch lining board, improve the cooling liquid circulation system, so that the installed level of the whole grinding machine can be improved.

After more than two years of operation, the cooling liquid purification system of grinding machine has basically achieved the expected goal and effect. The main performance is as follows: the efficiency of the grinding machine is increased to 1.5 times of that before the transformation, the main reason is that the coolant is thoroughly purified, the use effect is significantly improved, and the time for the fine grinding and polishing of the roll is reduced.

In addition, the auxiliary time for replacing the coolant and cleaning the grinding wheel is also significantly reduced. The quality of cold rolled plate is improved mainly because of the improvement of roll grinding quality and two grades of surface roughness. The service life of the coolant was extended and the production cost was reduced. The service life of the coolant was increased from 15 days before the modification to 45 days.

Buy Auto Cleaning Iron Removing Permanent Magnetic Separator for Conveyor Belt,Brands,Buy,Cheap,China,Custom,Discount,Factory,Manufacturers,OEM,Price,Promotions,Purchase,Quality,Quotes,Sales,Supply,Wholesale,Produce.